News releases

Danieli Corus India wins prestigious Kalinga Safety Excellence National Award

Order for SAIL IISCO Greenfield Mega Blast Furnace No. 6

Expansion into pelletizing technology

Sixth Greenfield Blast Furnace Commissioned for Hoa Phat Dung Quat

Order for twin Hot Metal Desulphurization Stations from JSL Ferrous Limited

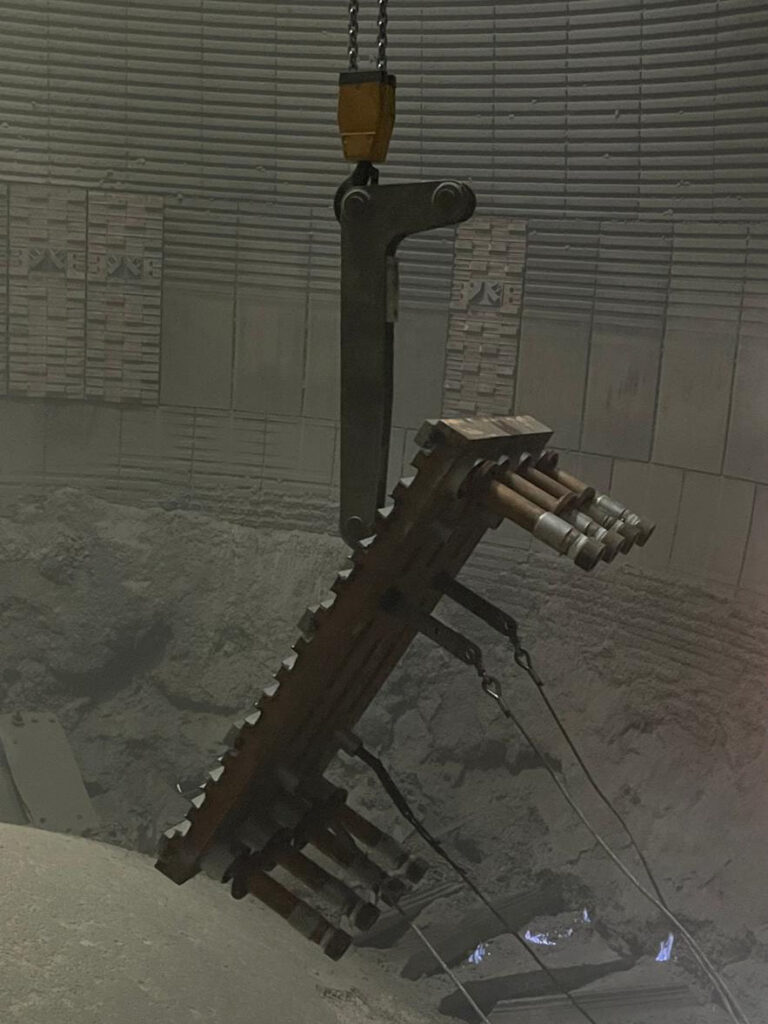

Order for Staves Replacement for RINL Blast Furnace No. 3

Order for Sublance Installed Base Management from JSW Vijayanagar Metallics Limited

Order for Additional Sublance System for JSW Steel Dolvi Works

First Greenfield Blast Furnace at Hòa Phát Dung Quat Phase II Plant Starts Operation

Order for Sublance System from Hebei Huaxi Special Steel

New Converter for AG der Dillinger Hüttenwerke Commissioned

Jiangsu Shagang 5800 m3 Blast Furnace No. 4 restarts production after conversion to plate cooling