Sublance Systems

Danieli Corus sublance technology is the ultimate technology package, serving the operator critical process information such as the bath temperature, bath level, carbon and oxygen content as well as a steel sample without interrupting the process. The sublance provides this vital heat information in the shortest possible time with highest degree of reliability and accuracy. This helps increase productivity and improves process control—but above all, it provides a safer working condition for shop floor personnel.

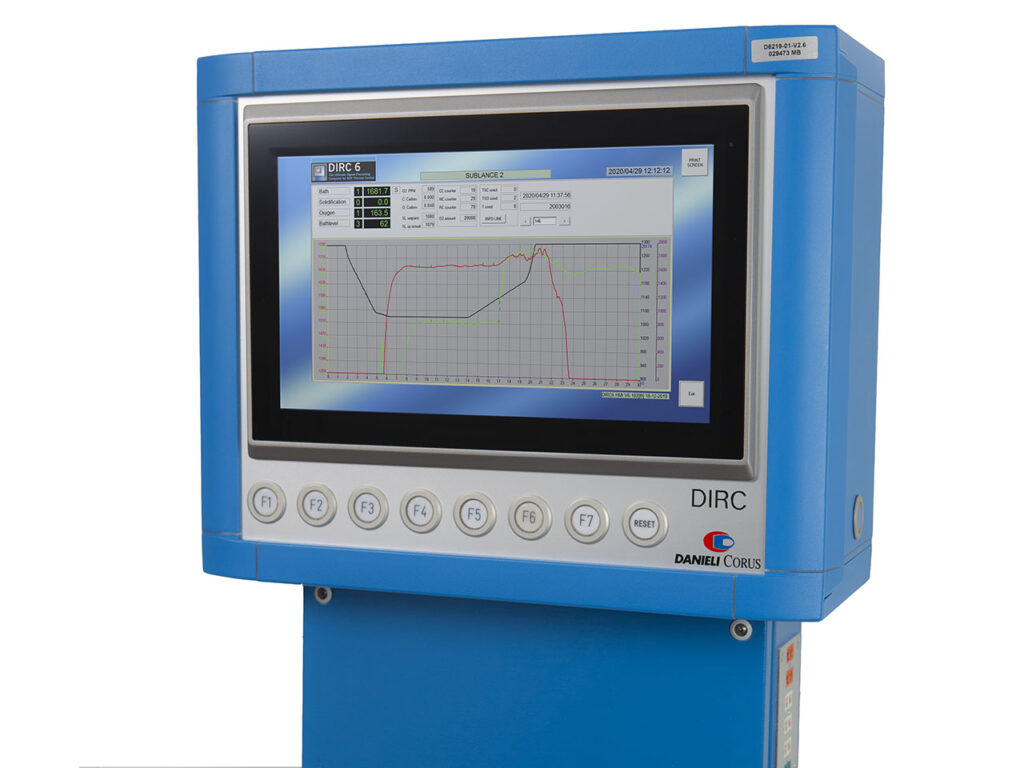

Speed and Accuracy: DIRC VI

The Danieli Corus sublance system has the shortest possible cycle time in the industry, from connecting a probe sensor to reliably processing of the signals. The immersed probe sensors feed their signals, which are then analyzed and displayed to the operator, while the system also collect a sample for laboratory analysis. In order to ensure that signal processing is of the highest accuracy and within the shortest time, Danieli Corus has developed a proprietary system known as DIRC. This system is currently in its sixth generation, which has an enclosed operator display, but also allows for browser–based access.

Unparalleled Reliability

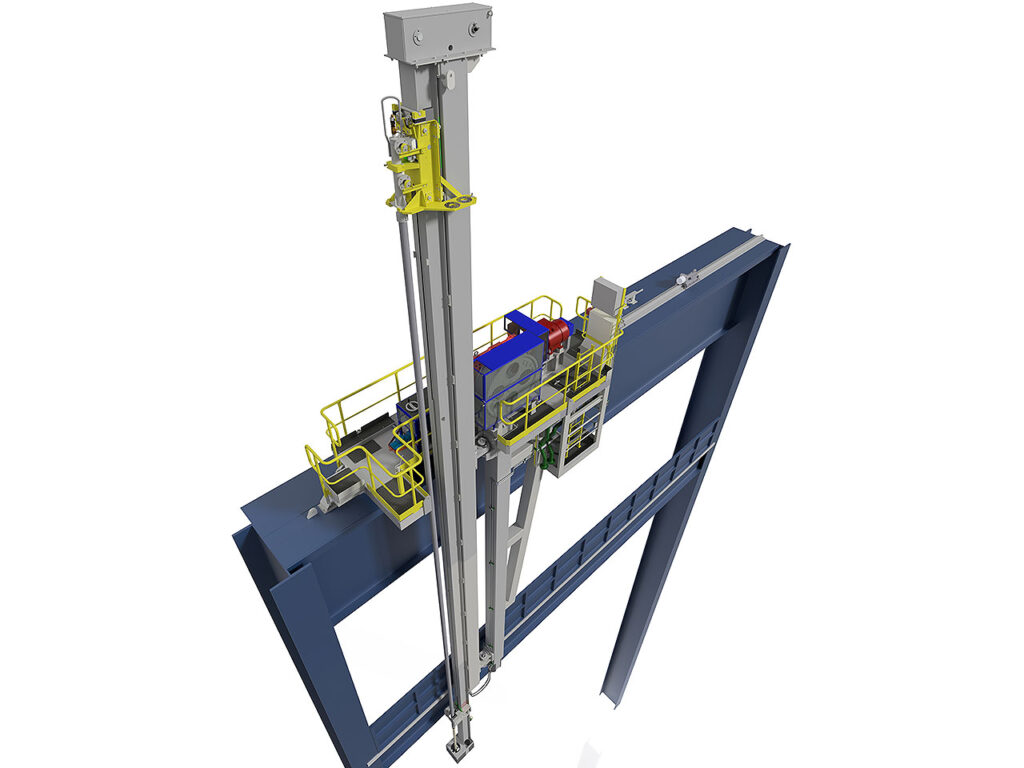

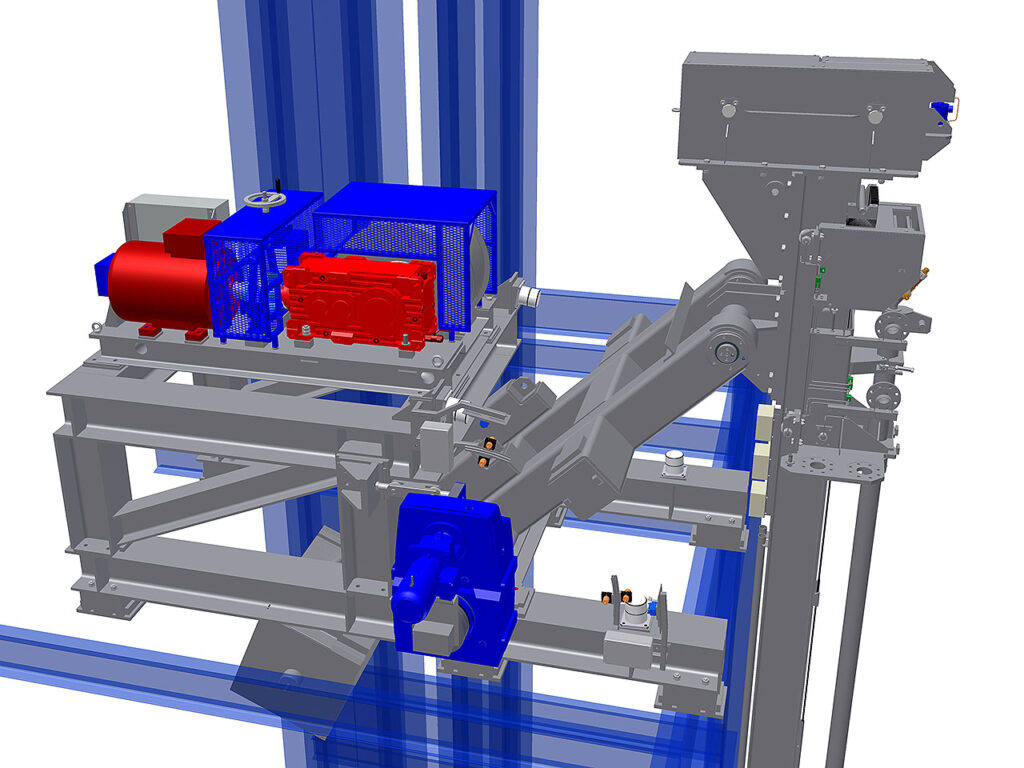

Danieli Corus sublance equipment is designed and manufactured to last for decades in the harsh environment on top of the converter hood. Our design employs simple, straightforward and proven arrangements rather than complicated and vulnerable components that demands more intensive maintenance and does not last as long.

Every piece of critical equipment is designed to be robust, considering ease of maintenance.

Tailor–made Installation

Retrofitting a sublance system in an existing BOF Shop can be challenging. Shop height might be insufficient or mounting might be hampered by space limitations or paths of movement that are impeded by other equipment.

Danieli Corus has retrofitted sublance systems in some of the most challenging shop layouts. If required, a laser–based 3D scan of the BOF Shop is made to assess potential arrangements. In one case, mounting points were aligned in a parallelogram shape to accommodate movement along a dogleg–shaped lance aisle. During another project, a counterweighted arrangement was developed to create a vertical lifting movement.

Based on comprehensive site surveys and with outside of the box thinking, solutions are found to overcome the restrictions found in every plant.

Featured references

Jiangsu Shagang Sublance Replacement

Systems Installed

163

tap–to–tap–time reduction

8 min

Scrap rate increase

1 %

Years of expertise

45

The Ultimate Tool

With Sublance–based BOF Process Control, operators are served process information as quickly and accurately as possible. This gives them the flexibility to take corrective actions and hit the target window for the heat, shortening tap–to–tap times while reducing the number of heat downgrades or repairs. Together with the exceptionally high utilization rates of Danieli Corus sublance systems, this will ensure consistent, stable and safe BOF Shop operations to achieve the desired targets of shop output, safe working conditions and operational cost optimization.