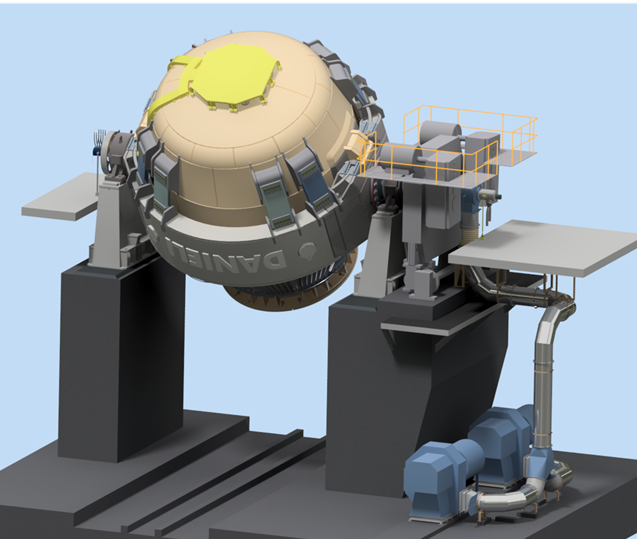

BOF Steelmaking Converters

Since Danieli Corus entered into converter revamping activities in 2012, contracts for as many as 18 converters were awarded. With tapping weights ranging from 65 to 350 tonnes, new converters were supplied and commissioned for the most demanding steel producers around the world—all of which fully tailored to the end user’s requirements.

Customized designs

Danieli Corus is in the unique position of being able to engineer and manufacture each converter vessel in accordance with every end–user’s specifications. With campaign length targets increasing, more and more steel producers require customized combinations of shell materials. Similarly, a variety of cooling arrangements (water– or air–based) may be incorporated into the design.

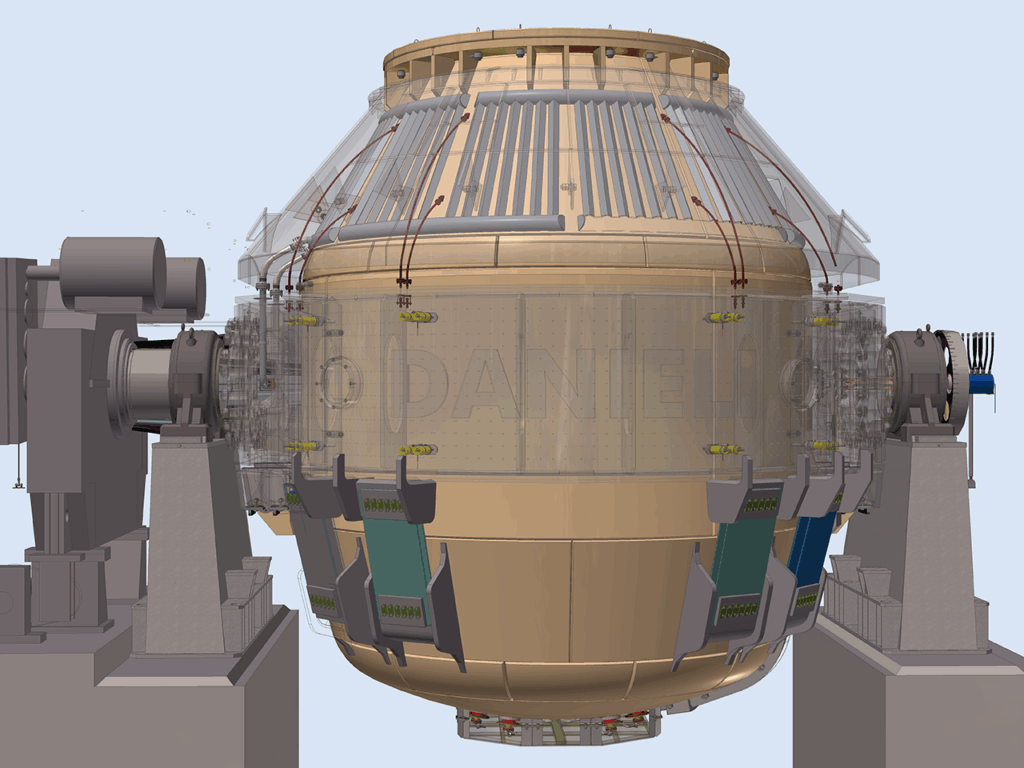

Maintenance–free suspension system

In rethinking the converter suspension system, Danieli Corus has reached sophistication through simplification. The suspension system has the task of stably carrying the converter load during rotation and particularly when the converter is in its horizontal position. The Lamella–based vertical arrangement and the patented DaniellaTM horizontal suspension elements are straightforward while inherently accommodating temperature differences between vessel and trunnion ring.

Online temperature and deformation measurement

In managing the converter vessel’s campaign, online information on shell temperature and deformation is of great value. To monitor these parameters, Danieli Corus developed the Q–Temp 2.0 system. Initial tests were conducted with voestalpine Stahl, installing three elements inside the trunnion ring of a converter. By 2024, all three converters at voestalpine Stahl Linz were equipped with these elements.

Q–Temp 2.1 includes an electric resistance for measuring deformation. It was installed in a at voestalpine Stahl, showing promising results. A 240 tonne converter in Latin America was also equipped with Q–Temp 2.1 elements.

Featured references

Dillinger Hüttenwerke Converter

Converters

18

Minimum tapping weight

65 t

Maximum tapping weight

350 t