Blast Furnace Level 2 Automation

Low cost Blast Furnace Ironmaking requires low coke rates, typically below 300 kg/tHM. This drives a number of process parameters towards their limits and increases the pressure on the operator. The Danieli Corus Blast Furnace Automation System was developed by ironmakers–for ironmakers, with the objective of supporting the operator’s efforts to optimize the process without limitation.

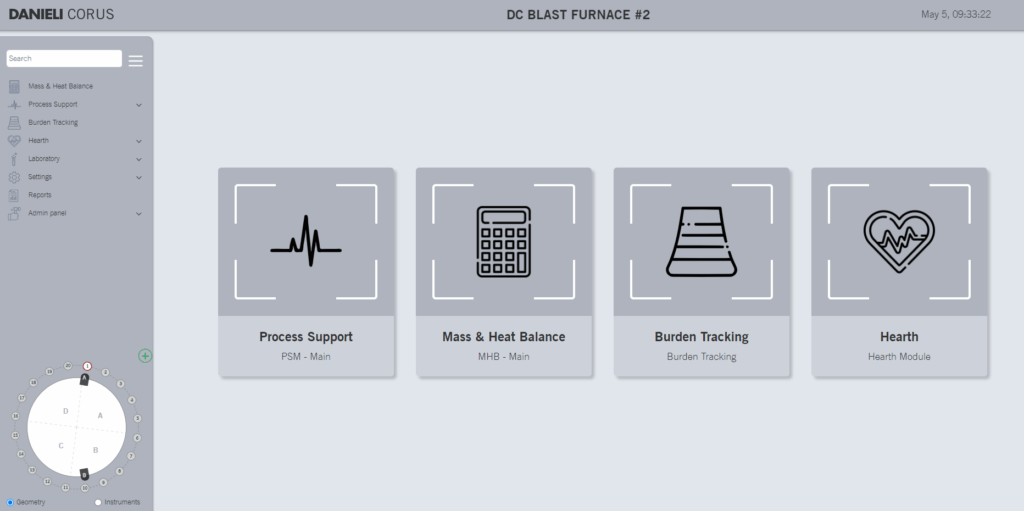

Browser–based and modular

The current, third generation of the Danieli Corus Blast Furnace Level 2 Automation System represents a great step forward in terms of user–friendliness. The user interface is browser–based, allowing for easy access from anywhere in the plant. Online process data and operator advice are presented such that the operator is liberated of the tedious tasks of data analysis and process calculations and can focus entirely on optimizing process stability and efficiency.

The system’s architecture is entirely modular, allowing for partial or full implementation of the system depending on requirements.

Process models based on operational experience

Process models are the very backbone of our process automation system. Analyzing real–time furnace behavior, enabling predictive control and early detection of process anomalies. The models enable higher productivity at the lowest cost and emissions while maintaining process stability.

The models developed by Danieli Corus are based on 50 years of global experience in blast furnace ironmaking—matching the process know–how of the experts in the blast furnace control room.

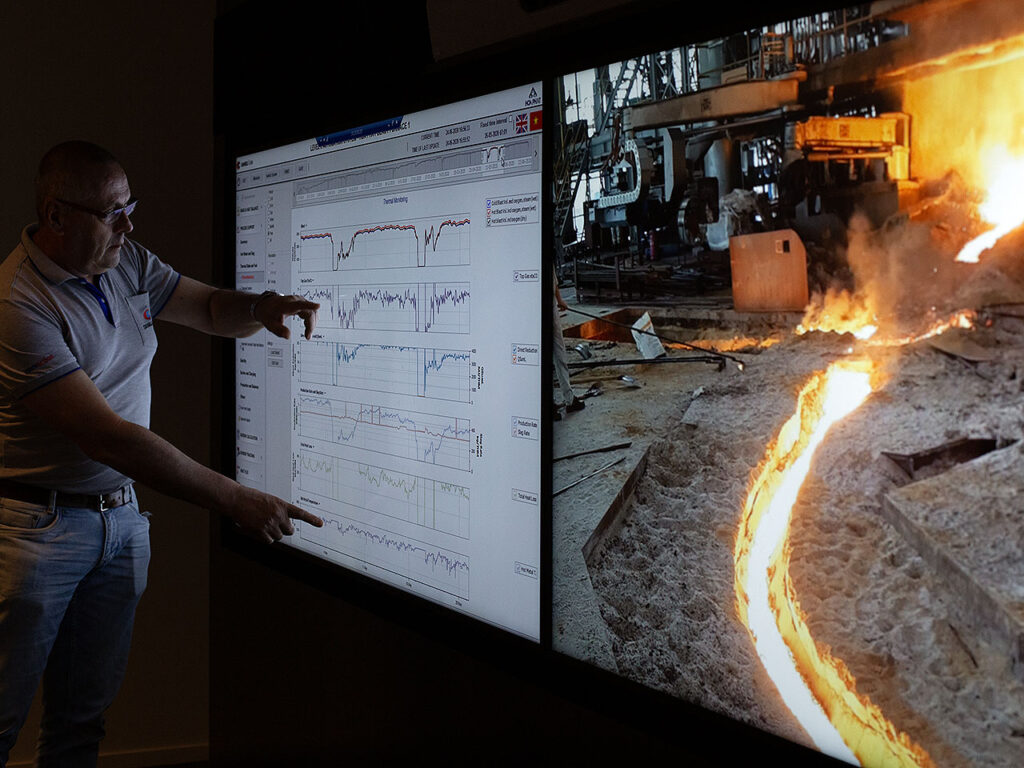

Ready for remote support

The Danieli Corus Blast Furnace Level 2 Automation System can be configured such that remote monitoring of the process data is possible. With this option enabled, ironmaking experts working at an off–site location can join the operating team in redeveloping process setpoints to overcome challenging conditions or to improve process performance and economy.

A Blast Furnace equipped with this system opens the door to more frequent and more cost–effective deployment of the unique operational assistance services offered by Danieli Corus.

References

49

Generation

3 rd

Years of experience

40

Retain the human factor

We believe that for stable, reliable and efficient blast furnace operations, the operator should always remain in control of the blast furnace process—automation systems, including their advanced process models and even artificial intelligence applications, are available to eliminate human error rather than the human factor.

The complexity of the blast furnace ironmaking process and its long response time to process measures imply that experienced, knowledgeable operators are indispensable. An automation system informs the operator and provides advice, empowering the operator to optimize the process without experiencing a single limitation.