Plant Assessments

Within an integrated steel plant, a significant part of the plant’s cost and emissions are determined in the primary end. On top of that, the liquid section is critical in terms of risk, continuity and output. The value of solid information to support investment plans, maintenance strategy and operational setpoints cannot be overestimated.

While internal teams possess unmatched insight into process and equipment conditions, their close involvement can lead to blind spots—where routine, familiarity, or unintentional bias may cause them to miss hidden risks or untapped opportunities. External experts bring objectivity, fresh perspectives, and specialized knowledge. With experience across many continents and cultures, they apply best practices and benchmark performance effectively.

Focus areas

The objective of any plant assessment project is to establish a baseline campaign management program that accommodates the objectives stipulated in the plant’s strategy. Such a program is analyzed based on three main components:

- Raw Materials – quality and variability directly impact plant performance. Based on the parameters of the available raw materials, a burden can be designed for stability, efficiency and consequences for plant equipment

- Process – a review of operating practices combines the analysis of process data, operator insights and emissions against day to day performance

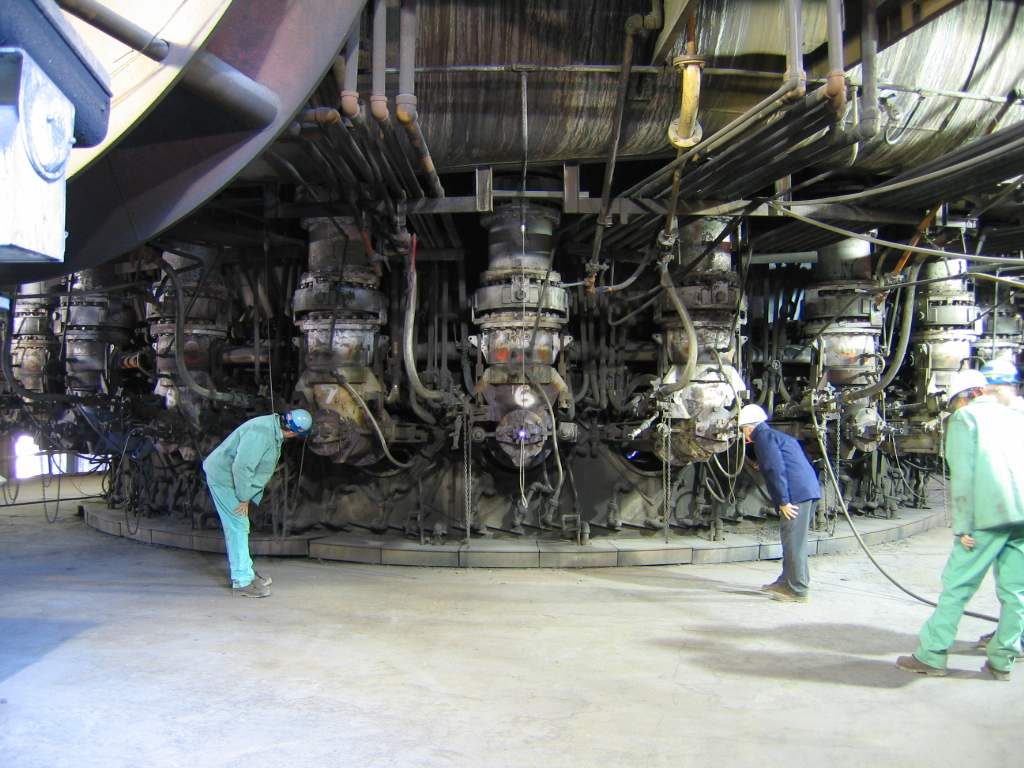

- Equipment Condition – maintenance condition and remaining lifetime capability of equipment are assessed based on the mechanical properties of e.g. the shell and static equipment as well as refractories

Actionable scenarios

After raw materials, process and equipment are assessed, potential measures are placed on a timeline in order to develop a campaign management program that combines required capacity, anticipated remaining campaign length and emission requirements. Using a structured approach based on cost and effect of these measures, the suggested program is finalized and agreed upon to match the overall plant strategy.

A schedule of activities, each of which duly assessed for effort and impact, is practical since its development is implementation–driven. The scenarios allow for step–wise implementation with or without the support plant engineers and contractors.

Plant Assessments

99

Consultancy and Study Projects

44

maintenance

8

years of experience

43

More than just a health check

An audit program is more than just a health check—it’s a strategic tool that delivers unmatched clarity for confident strategic decision–making. It empowers operating and maintenance staff to plan interventions at precisely the right moment. By uncovering hidden inefficiencies and risks, the audit helps safeguard production targets with consistency and control. It’s a smart investment that turns insight into action—ensuring sustainable, repeatable performance and driving long–term value across your operation.