Blast Furnace Operational Assistance and Process Support

The blast furnace is a complex, counter–current reactor, presenting various challenges that require stability and efficiency. Leveraging 50 years of experience and technical expertise, our consultancy optimizes blast furnace operations with tailored solutions. We integrate advanced technologies and best practices to ensure efficient and consistent performance, empowering your operational team with innovative strategies and actionable insights.

Our goal is to drive sustainable growth and long–term success by enhancing efficiency and optimizing performance. Whether a remote or on–site approach is employed, our team is always ready to help the client’s team reach and exceed its objectives.

Our team helps you achieve low fuel consumption levels, which is crucial for reducing greenhouse gas emissions as well as cost per tonne of finished product. By integrating state–of–the–art technologies and expert strategies, we optimize blast furnace operations to ensure minimal fuel usage and maximum efficiency and process stability. You can rely on us for innovative solutions that drive both economic and ecological benefits for your blast furnace ironmaking operations.

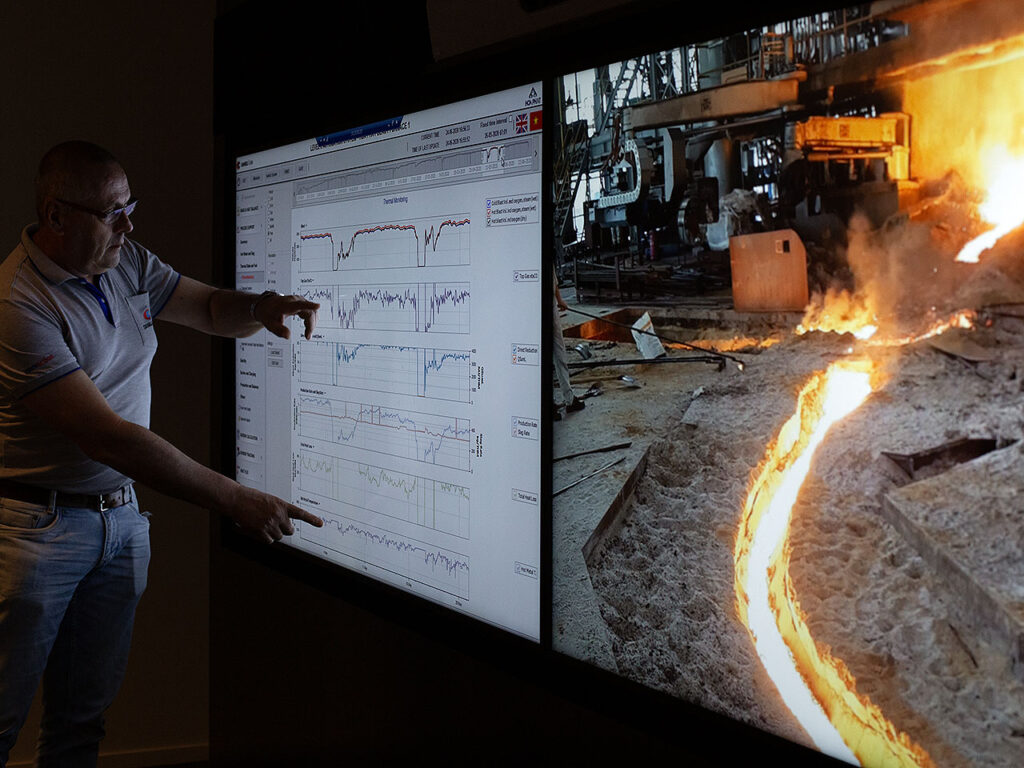

Remote Services

Remote operational assistance is available for several operational procedures such as blow–in, blow–down, process optimization and even chilled hearth recoveries. The team ensures a hands–on approach to find the best solutions, leveraging extensive experience and technical expertise.

A great advantage of using remote operational assistance services, is that external expertise can be made available on much shorter notice and more cost–effectively since it is easier to fit in the expert’s schedule while saving travel time—and cost.

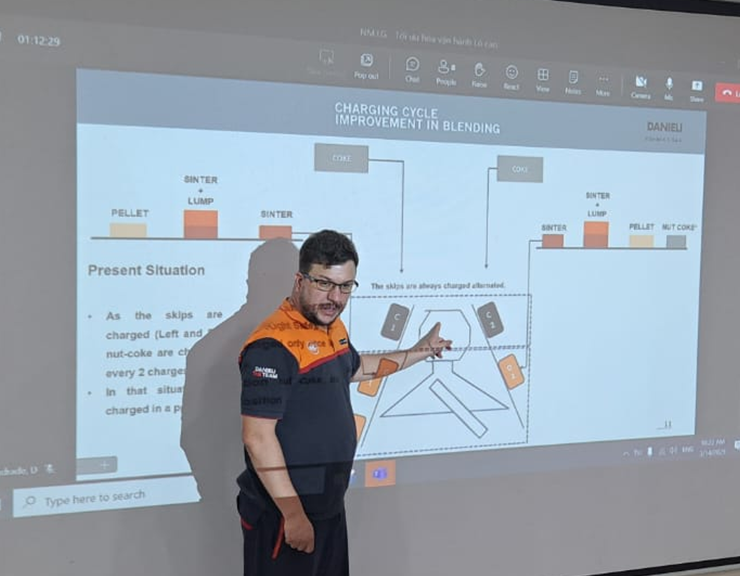

Training Programs

Our on–site training programs are an additional option for attaining long–term operational improvement. These courses provide fundamental understanding of the modern blast furnace ironmaking process based on the same 50 years of experience as our operational assistance services.

We also offer a “Train the Trainer” module, which empowers selected staff to become in–house instructors. This further ensures long–term knowledge retention, scalable training, and alignment with plant–specific practices. The approach fosters a culture of continuous improvement, staff empowerment and enhances operational consistency.

Projects

340

Chilled Hearth Recoveries

48

Operational Improvement Projects

68

Blow–in projects

30

Benefit from 50 years of global experience

During the myriad of operational assistance projects completed on all continents, our experts have accumulated unparalleled expertise on the blast furnace ironmaking process, but also on how operational practices and set–points are developed within a wide variety of companies and cultures. Their experience is at your disposal for improving as well as debottlenecking or even recovering your operations.

Danieli Corus have a history of highly effective and consistent performance, driving sustainable growth and long–term success.