Jiangsu Shagang 5800 m3 Blast Furnace No. 4 restarts production after conversion to plate cooling

On 27 June of this year, a joint team of Shagang and Danieli Corus ironmaking experts has successfully restarted Jiangsu Shagang Group’s Blast Furnace No. 4 after a modernization project. Though during the prior campaign, the furnace had consistently met Shagang’s ambitious production targets, the client’s added requirement for the new furnace was to achieve a longer campaign length.

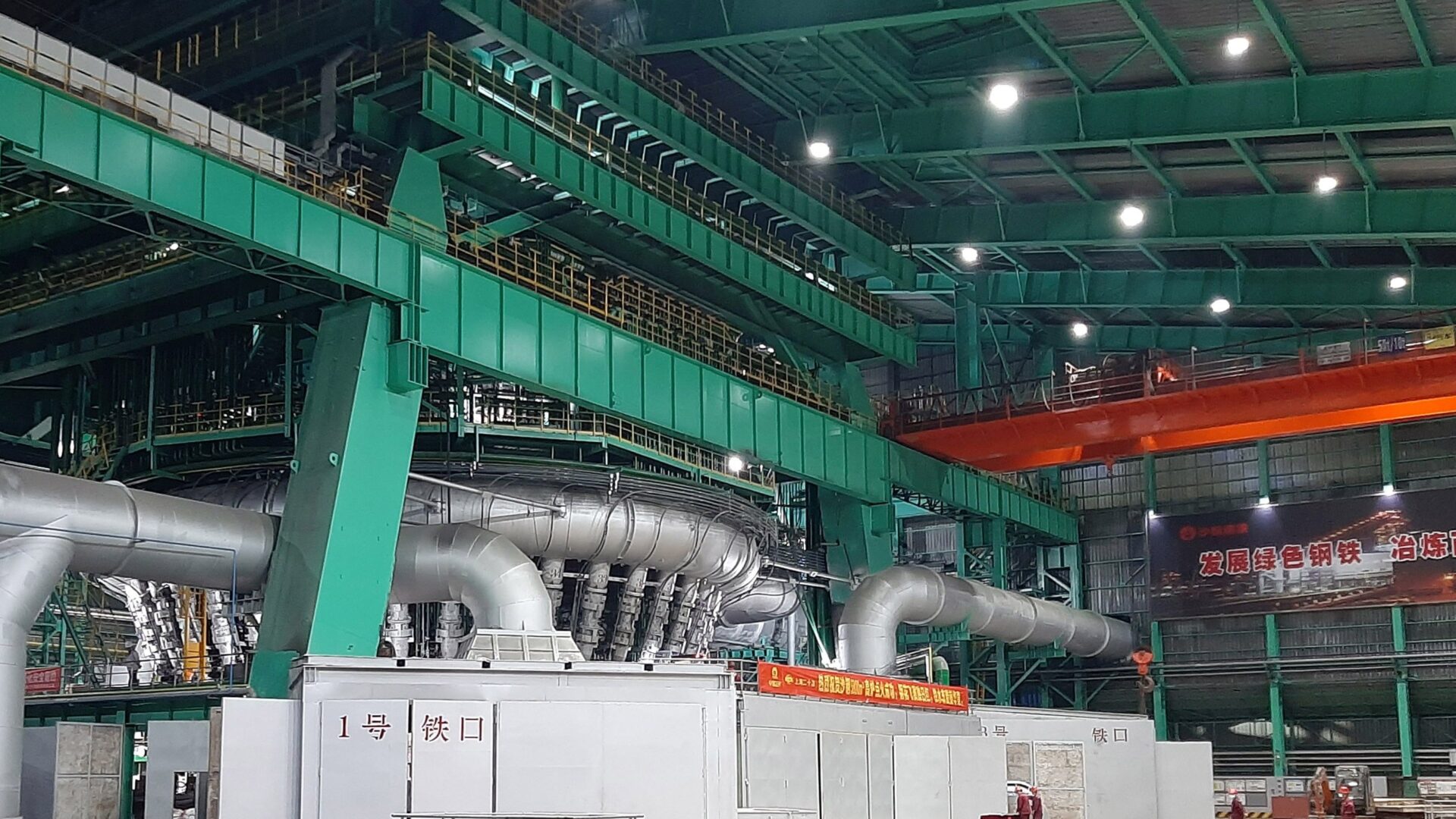

China’s largest Blast Furnace

Zhangjiagang Blast Furnace No. 4 was originally built in 2008 and commissioned in 2009. A contract for a modernization project was signed in 2022. Under this project, the bosh, belly and lower stack zones were converted to the acclaimed high–conductivity lining design based on plate coolers and graphite refractories promoted by Danieli Corus. This is the only foreign blast furnace design that is embraced by the Chinese steel industry, with the Taiyuan Blast Furnace Nos. 5 and 6 operated by TISCO having been converted earlier. With a 5800 m³ volume, Shagang No. 4 in China’s largest blast furnace. It was designed to produce 14,000 tHM/24h.

Operational results

After start–up, the Shagang and Danieli Corus teams continued to work together to ramp up the furnace while at the same time monitoring shell temperatures in order to assess proper functioning of the cooling system. Even in high heat load areas, shell temperature remained below 80 °C.

Process optimization was a challenging process given the ambitious production target and changed raw material properties. Through improved burdening, burden distribution, process control and casthouse operations, these challenges were overcome. Despite the higher slag rates, operators were able to attain record coke rates below 320 kg/tHM.

We are confident that China’s largest blast furnace will stand as a flagship for both Jiangsu Shagang Group as an end user and Danieli Corus as a technology provider.