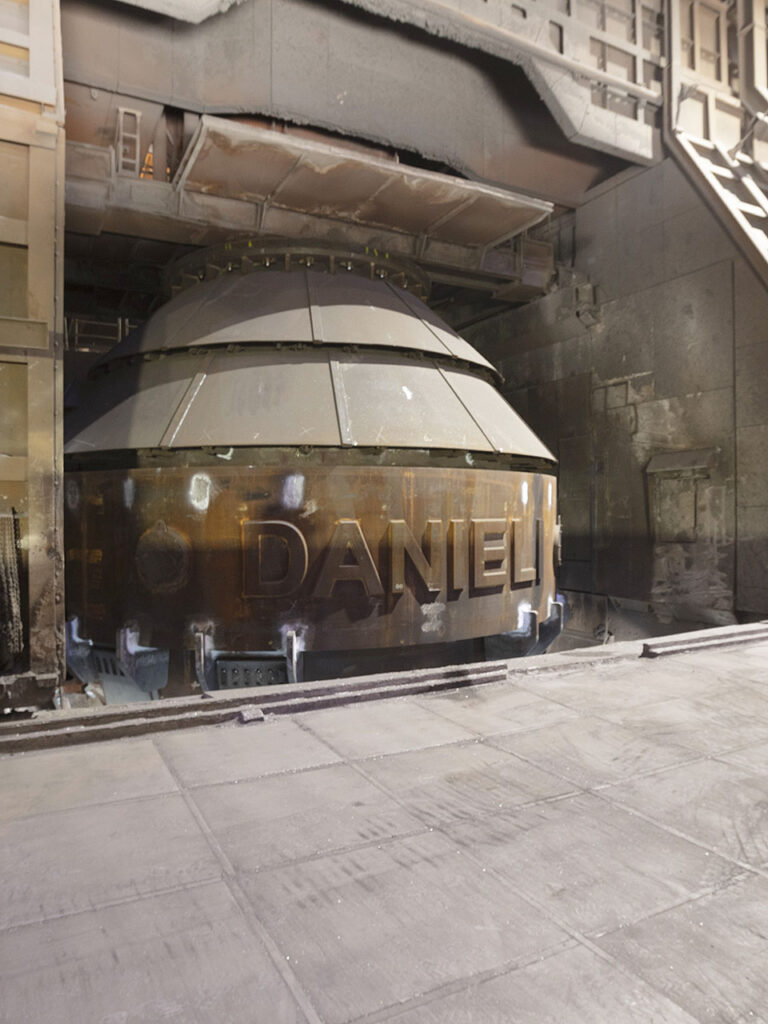

New Converter for AG der Dillinger Hüttenwerke Commissioned

AG der Dillinger Hüttenwerke and Danieli Corus have started steelmaking operations with the new 200 tonne Converter No. 1 at the Dillinger BOF Shop. The EPC revamp project, which had the objective of enabling a long campaign life under the challenging conditions of the high–performance operations at Dillingen, included the replacement of the converter vessel, trunnion ring and parts of the tilting drive.

Converter design

To the client’s specification, the entire vessel was manufactured out of P420 MHT, a proprietary grade produced by Dillinger Hüttenwerke. The vertical suspension uses eight Lamella elements, while the horizontal suspension relies on DaniellaTM technology. The converter is equipped with a detachable bottom for reduced reline times.

Project completion

Together with the contractor, Danieli Corus managed to complete the converter replacement within a shut–down period of 37 days. Deliveries and erection activities were completed in time and quality of all equipment was fully on–spec.

All parties involved look back at a fruitful cooperation with a successful project as an excellent outcome.