Pulverized Coal Injection System for Dearborn “C” Blast Furnace

During the implementation of Pulverized Coal Injection at Dearborn “C” Blast Furnace, the main challenge was to integrate the handling of coal that had been pulverized at an off–site location given the client’s decision to secure pulverized coal from an external source. The project was completed by as many as twelve suppliers and sub–suppliers, adding further complexity to the execution. Teamwork made this project a great success.

Coal supply

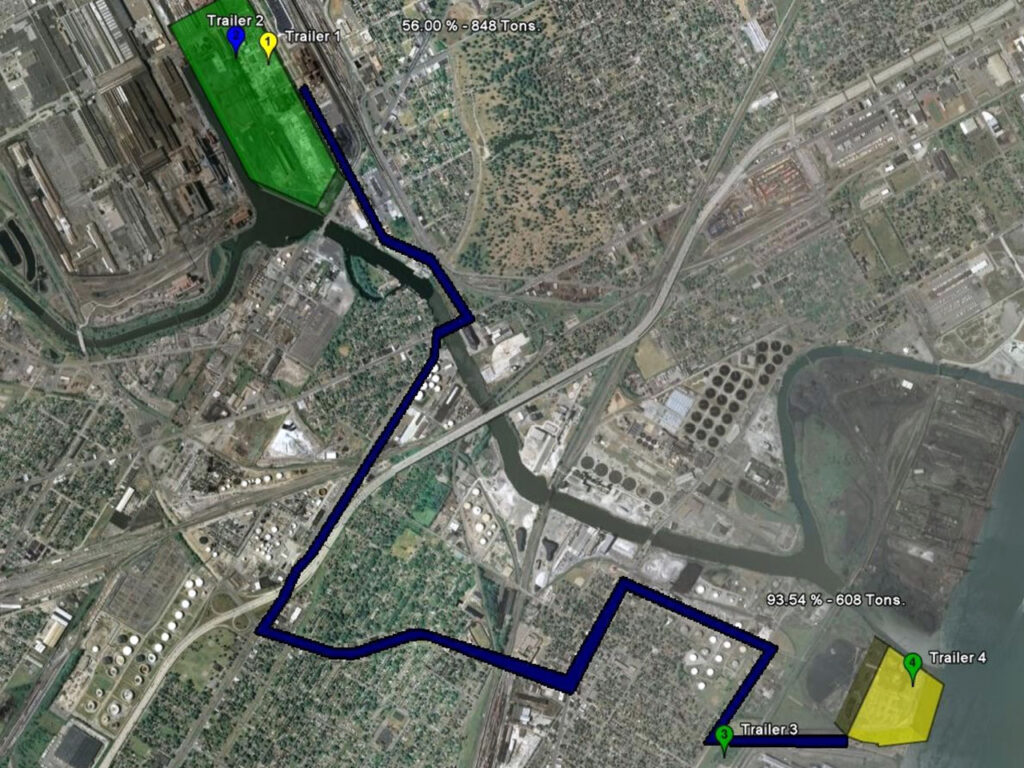

Even when a 60 t/h injection rate is easily matched by a 60 t/h off–site grinding capacity and a theoretical 60 t/h trucking capacity, having coal supply keep up with the actual injection into the furnace can be a challenge owing to e.g. varying traffic conditions. A tracking system was developed for the dedicated trucks, using not only GPS but also data transfer for communicating parameters such as coal quality and shipping weights.

coal handling

Trailers were redesigned to accommodate larger supply and discharge lines in line with required capacity while keeping them compliant with road and highway regulations. Automation for the redesigned trailers was maximized to reduce the scope of work for driver during loading and unloading. This resulted in coal delivery in pace with the furnace process—at zero spills during handling.

coal injection

Though this system for handling pulverized coal supplied by off–site grinding facilities can be combined with any injection principle, the Dearborn furnace relies on dilute phase injection with passive control—using injection lines with equal pressure drop for injection rates of up to 220 kg/tHM matching the symmetry of the hot blast.

"*" indicates required fields