Chilled Hearth Recovery and Process Restarts with Oxy–Fuel Technology

During the lifetime of a blast furnace, various situations can lead to extended shutdowns or reduced productivity, such as chilled hearth, emergency repairs, intermediate repairs, shotcrete repairs, or long outages where the salamander was not tapped. Restarting the furnace requires careful planning and execution. An emergency blow–in system for Blast Furnaces is recommended in this situation. The Danieli Corus Oxy–Fuel Technology was developed and fine–tuned over the years to deliver a safe and successful Blast Furnace restart.

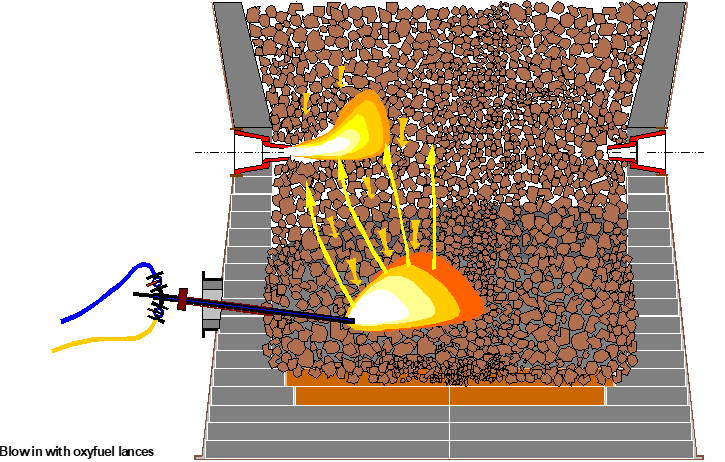

Oxy–Fuel Technology

The Oxy–Fuel technology was developed with the objective of introducing large amounts of oxygen and fuel gas in the blast furnace hearth through the taphole, using a refractory protected lance. The remaining coke inside the hearth will react with the oxygen, generating heat enough to melt the solidified hot metal and slag. The burning of the coke promoted by the Oxy–Fuel lance generates voidage in the hearth, helping to improve local permeability to the system supporting a better recovery of the Blast Furnace.

The Oxy–Fuel Technology enables fast and reliable Blast Furnace Recovery compared to traditional methods. Additionally, the Danieli Corus team offers comprehensive operational assistance during the Blast Furnace recovery process. This support ensures that every step is executed with precision, resulting in a successful restart and optimized performance.

More than 50 successful recoveries worldwide

Danieli Corus has a long–standing history of successfully executing Blast Furnace Recoveries utilizing the Oxy–Fuel Technology. From the initial planning stages, our team of specialists provides unwavering support and guidance to ensure the achievement of optimal results. With the extensive experience of more than 50 successful recoveries globally, our dedicated professionals stand ever-prepared to assist in every aspect of the process. This expertise guarantees a meticulously planned and executed recovery, leading to the seamless restart of the Blast Furnace and its continued optimized performance. The Oxy–Fuel Technology’s benefits, coupled with our team’s comprehensive operational assistance, provide a robust foundation for reliable and efficient Blast Furnace operations.

"*" indicates required fields