Ma’aden Aluminium Fume Treatment Centers

Danieli Corus supplied two Fume Treatment Centers for the anode baking furnace at the new aluminium smelter built by Ma’aden Aluminium in Ras Az Zawr, Saudi Arabia. The systems have a gas flow processing capacity of 180,000 and 245,000 Am³/h and are entirely based on the acclaimed Pleno V dry scrubbing technology.

Vertical Radial Injector

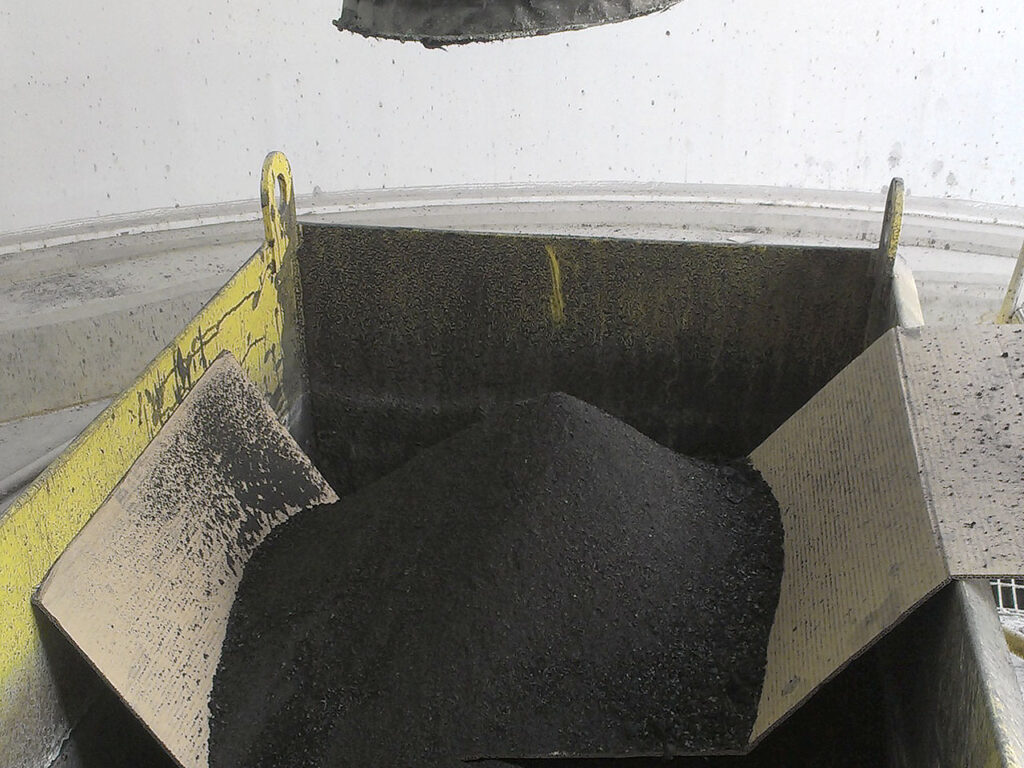

The heart of the Pleno V technology is the patented

Vertical Radial Injector (VRI). The alumina scrubbing

medium is injected into the reactor through the VRI

to achieve maximum diffusion of the particles in the

gas stream with minimum turbulence.

Conditioning Tower

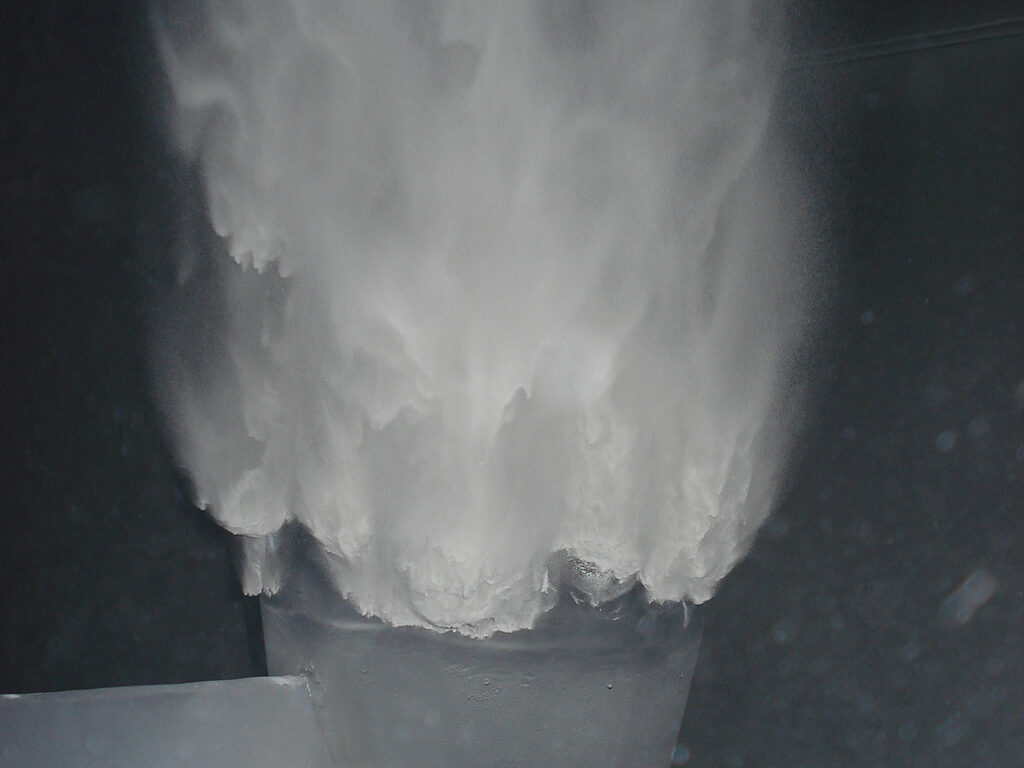

When applied at anode baking furnaces,

the Pleno V technology incorporates

an evaporative cooling tower upstream

of the scrubber to condense the

hydrocarbons. Accurate temperature

control ensures complete evaporation

of the water spray, yielding a dry

bottom and eliminating the potential for

corrosion.

Maintainability

Starting from its first generation, this technology was developed from the perspective of maintenance departments: with the objective of maximum availability and easiest maintenance. The system is layed out for accessibility and includes features such as walk–in plenum for easy filter bag replacement.

"*" indicates required fields