Jiangsu Shagang Sublance Replacement

After the successful implementation of Danieli Corus sublance technology at Zhangjiagang BOF Shop Nos. 2 and 4, Jiangsu Shagang Group awarded a contract for the replacement of the malfunctioning sublances of a competing western design at their BOF Shop No. 3—for three converters, each with a 180 tonnes tapping weight.

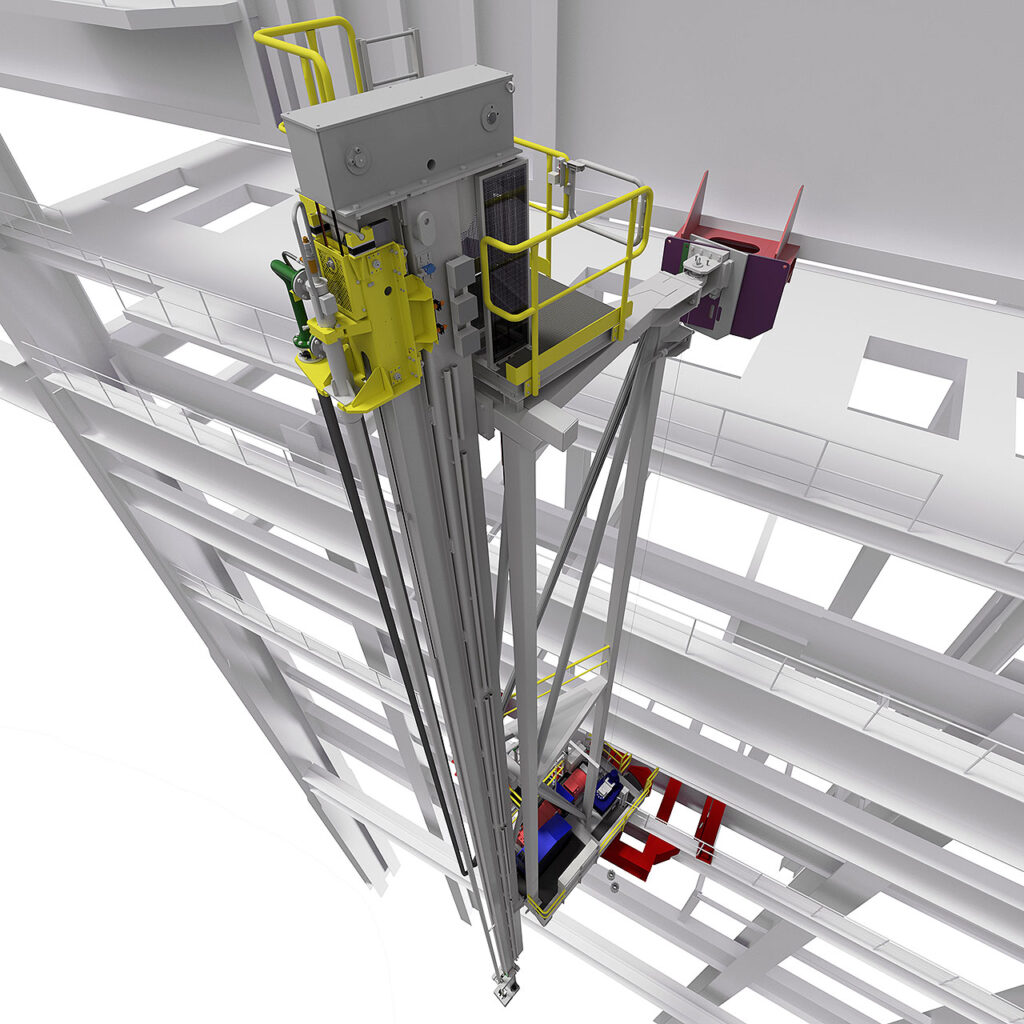

Indestructible Equipment

This client, one of China’s leading and fastest growing steel producers, had originally selected a competing European supplier for the sublance–based process control systems at BOF Shop No. 3 at their Zhangjiagang plant. These systems, however, failed to deliver the measurement cycle times required for the production targets for the BOF Shop. This was primarily accountable to the complicated mechanical arrangements. Danieli Corus sublance equipment is designed and manufactured for long time, trouble–free operation in the highly unfavorable conditions on top of the converter hood. The sublance and associated equipment have proven lifetimes in excess of 40 years.

Long–term Relationship

Before this replacement project, Danieli Corus had supplied and installed a total of five sublance systems for Zhangjiagang BOF Shop Nos. 2 and 4, for converters with tapping weights of 180 tonnes and 120 tonnes respectively. After completion of this project, Shagang selected Danieli Corus for the supply of an additional sublance system for a new converter at BOF Shop No. 4—in this project, the implementation of the AutoTAP system is also included. This project marks an excellent relationship of more than 15 years between a leading technology supplier and a leading end user.

"*" indicates required fields