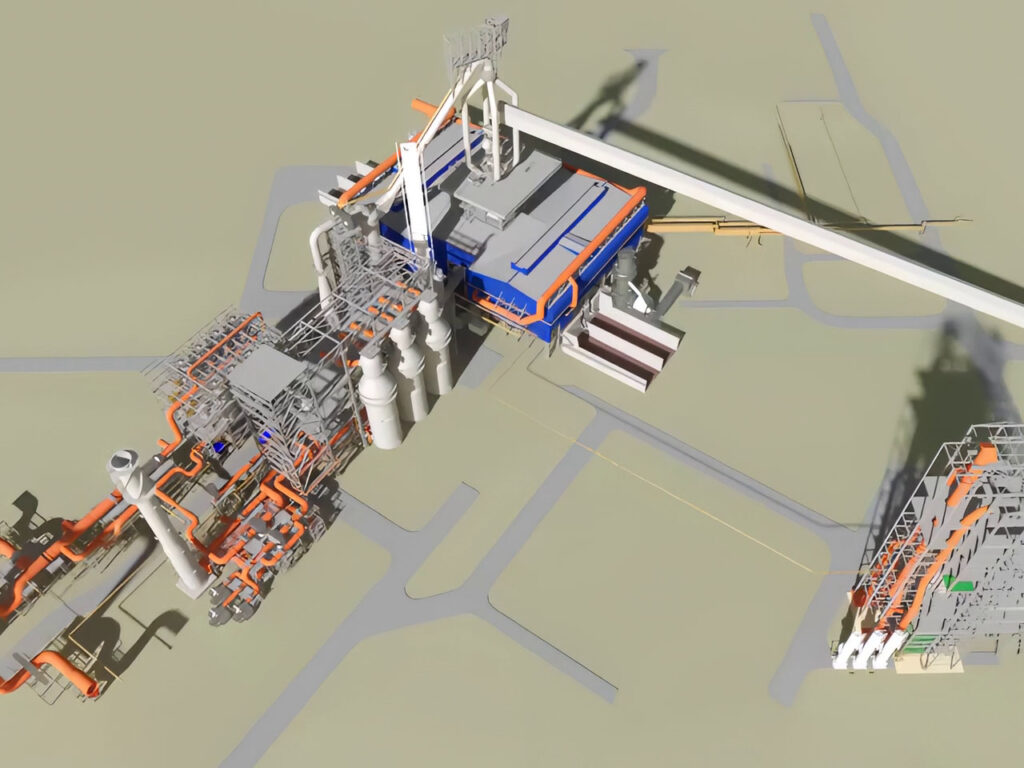

ArcelorMittal Nippon Steel India Greenfield Blast Furnace Nos. 2 & 3

ArcelorMittal Nippon Steel India selected Danieli Corus for the design and supply of their greenfield Blast Furnace Nos. 2 and 3 at their integrated steel plant in Hazira, Gujarat. Both furnaces will have a 3809 m³ working volume and are designed for a daily production of 10,000 tHM each. The bosh, belly and lower stack sections will be equipped with the “Hoogovens” integrated cooling and lining design: the indestructible bosh.

Prepared for Top Gas Recycling and Shaft Injection

The furnace proper design as well as the four–poster structures and platform lay–outs are designed to accommodate future installation of a secondary bustle pipe.

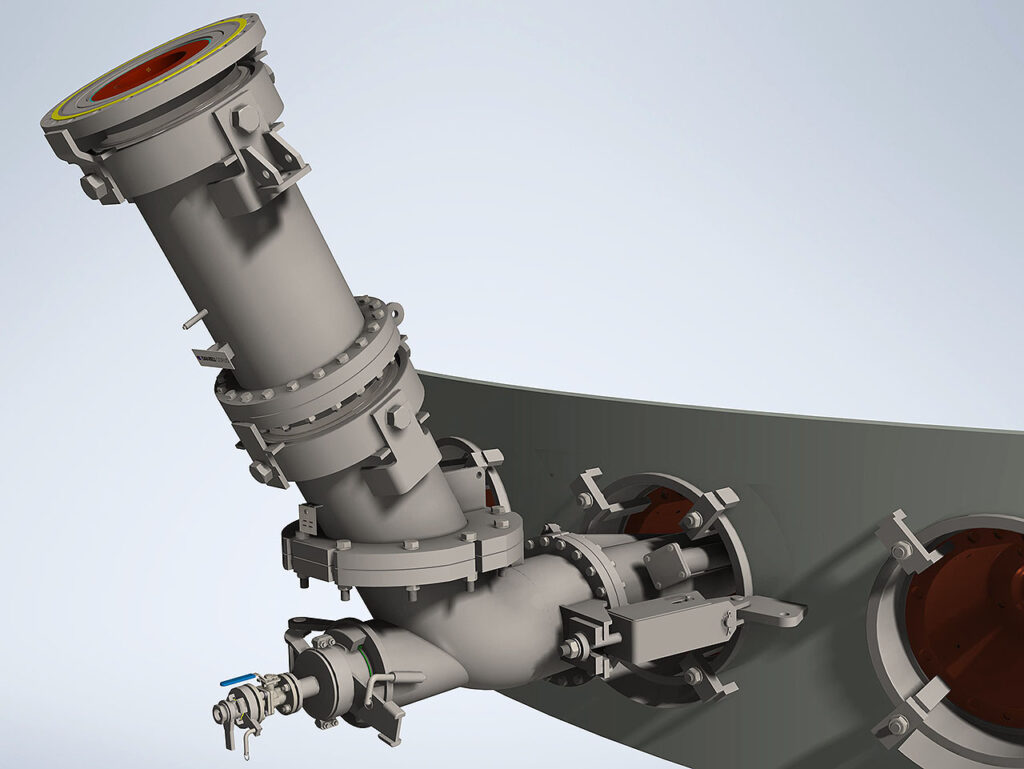

Hot Blast System based on Dome Combustion Design

Designed for an optimized footprint and maximum burner efficiency, the hot blast systems will rely on dome combustion hot blast stoves: a design that revolutionized hot blast stove technology—now equipped with the design features that have given Danieli Corus stoves their exceptional lifetime capability.

Well–Proven Dry Gas Cleaning Technology

Both blast furnaces will be equipped with a dry gas cleaning system. With now more than 65 references in the global metals industry, the gas conditioning tower and baghouse arrangement are a proven option for eliminating the use of large quantities of scrubbing water.

"*" indicates required fields